Building Like Blocks: The Magic of Prefabricated Buildings

In the assembly lines that operate like precision instruments in modern factories, beams, columns, walls, stairs and other building components are mass-produced like spirits that are given life. They carry the dream of architecture and are methodically transported to the construction site. There, like creative children building blocks, workers cleverly assemble and assemble these prefabricated parts. In the blink of an eye, a complete house appeared like a miracle. This wonderful building production mode, which is like building blocks, is the steel structure building that is attracting much attention today.

Recently, the reporter came to a prefabricated steel economical shopping center construction site. I saw a huge tower crane, like a giant steel beast, constantly waving its powerful long arm, lifting a piece of composite board accurately to the upstairs. Upstairs, the workers skillfully operated, the steel bars on the laminated board and the steel bars on the wall were tightly tied together. Subsequently, the site concrete such as a smart water flow, slowly injected, through this process, the composite board and beams, walls perfect integration, forming a strong and incomparable whole, like an indestructible steel fortress.

"In this project, part of the structure of a building uses prefabricated construction. These prefabricated steel economical shopping center were constructed by the prefabricated construction method. The whole process is like a high-tech magic show, first in the computer graphic design, carefully planning every inch of the building space; Then there is the structural design, which ensures that the stability of the prefabricated steel economical shopping center is as reliable as Mount Tai; Then through a series of complex and orderly processes such as production design, the accurate data is generated, and the production equipment is directly connected, and the building modules such as doors and Windows, stairs, and beams of the house are produced one by one. The construction site is like a large building block paradise, but these modules are spliced, assembled and built easily and efficiently." The project's architectural design commissioner proudly introduced to reporters. He also mentioned that the traditional way of building a floor area of about 1,000 square meters, it takes 70 workers to spend six or seven days of hard work, while the prefabricated steel economical shopping center only needs 25 workers to fight for five days to complete. If the whole steel structure building is completely fabricated, compared with the traditional construction method, it can save about 60% of the construction period, which is simply an efficiency revolution in the history of architecture.

"Compared with traditional concrete construction methods, prefab commercial exhibition hall are like a shining star in the field of architecture, with many dazzling advantages." You see, because the house components are carefully manufactured in the factory in advance, the construction site can no longer see a lot of mixing mortar scenes, and there is no need to build cumbersome formwork. This is like making a subtraction to the construction process, achieving the magical effect of saving water, materials and labor. Every drop of water, every piece of material, every piece of labor is put to the best use of resources." The design specialist grew more excited as he continued, "In addition to lightning fast construction, prefab commercial exhibition hall have the amazing advantage of minimal error. In traditional building construction, even the most experienced workers are difficult to avoid some subtle errors, which accumulate and may have an impact on the quality of the building. But the prefab commercial exhibition hall is different, it is in the factory production stage through high-precision mold and advanced technology, the error is controlled in a very small range. It is like putting on a tailored "precise coat" for the building, and every component can be tightly stitched together to ensure the high quality and stability of the entire building. This precision not only improves the quality of the building, but also provides great convenience for subsequent renovations and other work."

Moreover, prefab commercial exhibition hall also have excellent environmental performance. In the traditional building construction process, mixing mortar and building templates will produce a lot of construction waste and waste, which not only occupies land resources, but also causes pollution to the environment. The prefab commercial exhibition hall generates very little garbage at the construction site, which greatly reduces the pressure on the environment. At the same time, the materials used in prefab commercial exhibition hall also pay more attention to environmental factors in the production process, reducing the negative impact on the environment from the source.

In terms of building quality assurance, steel structure hospital also have unique advantages. Due to the strict quality inspection of each part when it is produced in the factory, every link has a detailed quality record, which is like issuing a "quality ID card" for each part. This allows in the construction process, if there is a problem with a part, you can quickly trace the source and solve it in time, avoiding the spread and accumulation of quality problems. This quality traceability system provides a strong guarantee for the long-term safe use of the building.

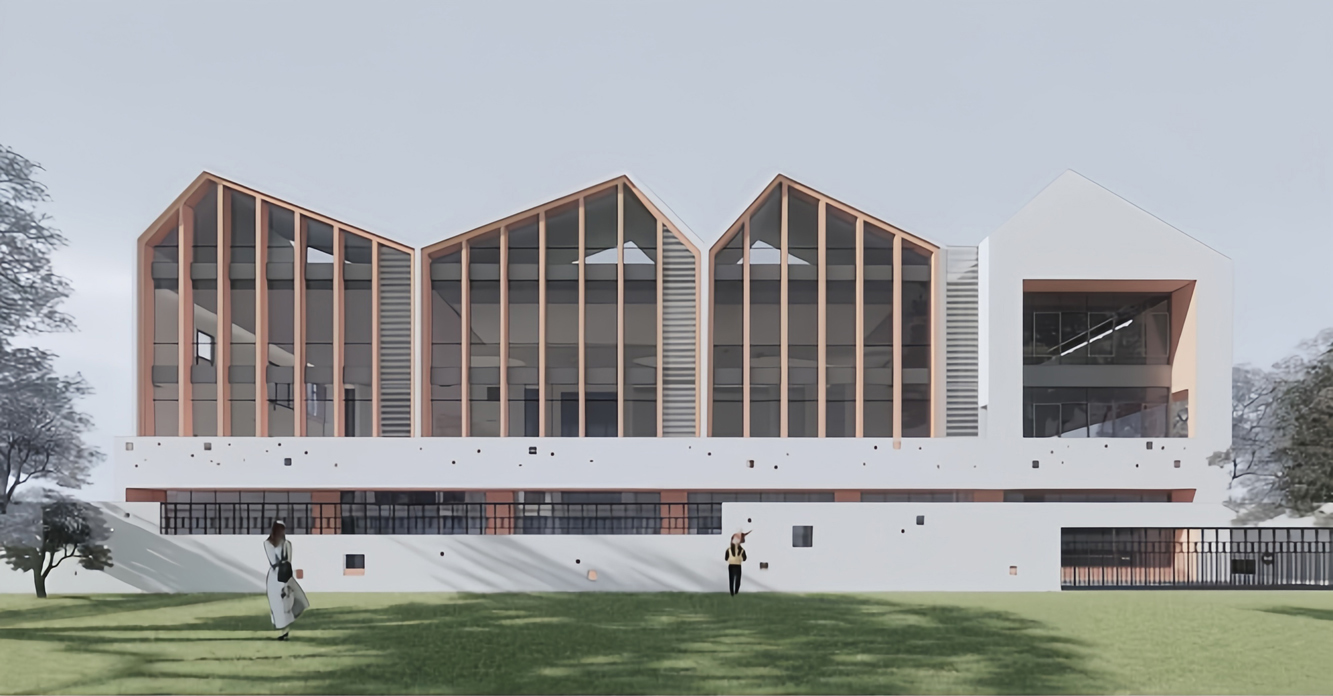

From the perspective of architectural design, steel structure hospital provide designers with a broader creative space. Designers can use a variety of standardized building modules, like Lego bricks, to create a unique architectural appearance and interior space. Whether it is full of modern geometric shapes, or the integration of traditional cultural elements of the architectural style, steel structure hospital can be easily achieved. Moreover, by changing the combination of modules, a variety of design solutions can be quickly generated to meet the individual needs of different customers.

With the continuous progress of science and technology, the development prospects of steel structure building are even brighter. In the future, we can expect more advanced production technologies and materials to be applied in the field of steel structure building. For example, new environmentally friendly and energy-saving materials can make the building more green and sustainable, and intelligent building modules can realize the automatic adjustment and control functions of the building. Perhaps one day, we will see buildings that are no longer static, but "intelligent living entities" that can automatically change their appearance and function according to the environment and user needs. At the same time, with the popularity of steel structure building, construction costs are expected to be further reduced, and more people will be able to enjoy the convenience brought by this efficient, environmentally friendly and high-quality building mode. This will not only change our living environment, but also have a profound impact on the development and construction of the whole city.